FRUIT LINES

For the processing of fruit, we make lines for all types of continental & tropical fruit: with stone, without stone, citrus fruit, tropical fruit. The scheme refers to a line with maximum flexibility but not optimized for specific products. The products that can be obtained are natural, concentrated, pasteurized or sterilized purees or juices.

FRUIT PLANTS

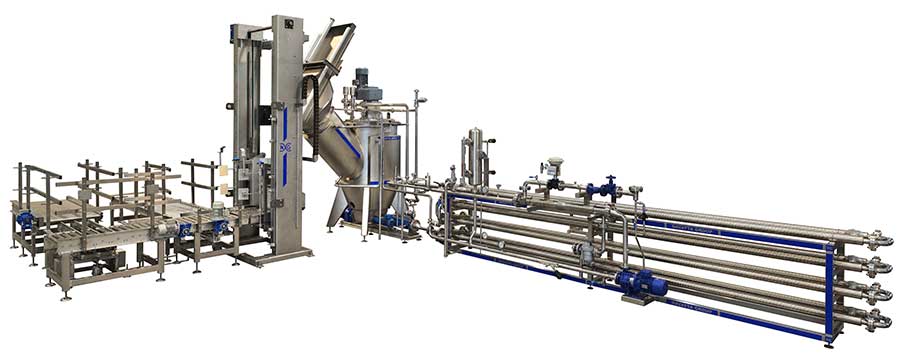

Mango and Acai extraction line

Mango and Acai extraction line

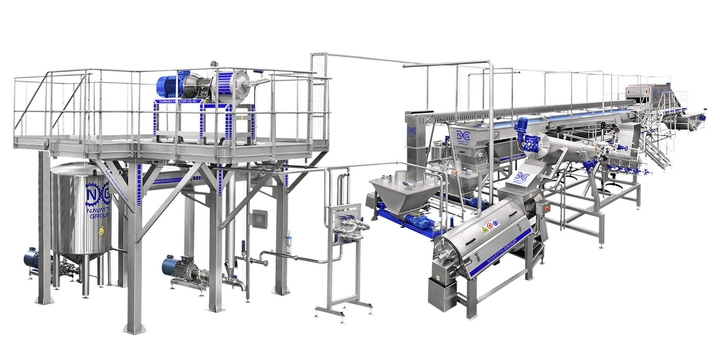

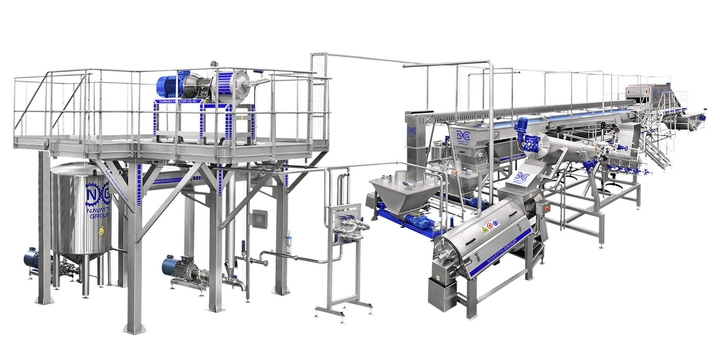

Tropical and Mediterranean fruit processing line: washing, water filtration, manual sorting, brushing, preheating and mango de-pulping, shredding, extraction of the puree

Stone cleaner for Mediterannean fruit

Ingredient Dosing – Mixing unit

Scraped surface pasteurizer

Formulates preparation line with rotary coil evaporator

Jam with pieces production line

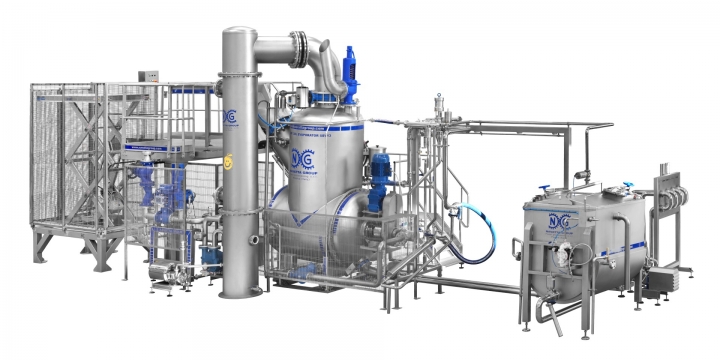

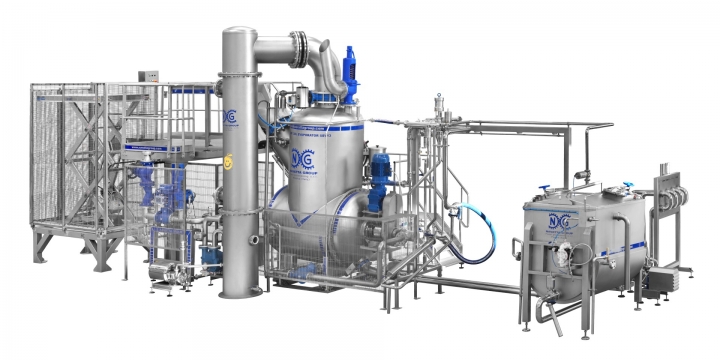

Mixed circulation evaporator (Forced Circulation + Falling Film) complete with hot break and aroma recovery

Mixed circulation evaporator (Forced Circulation + Falling Film) complete with hot break and aroma recovery

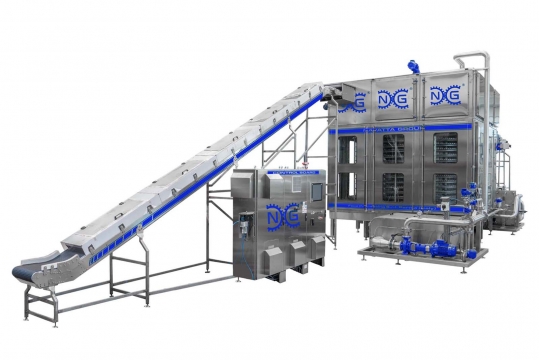

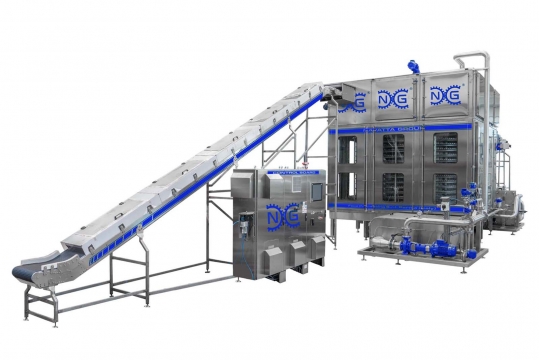

Spiral water pasteurizer - cooler – dryer tunnel for cups 114 – 128 gr.

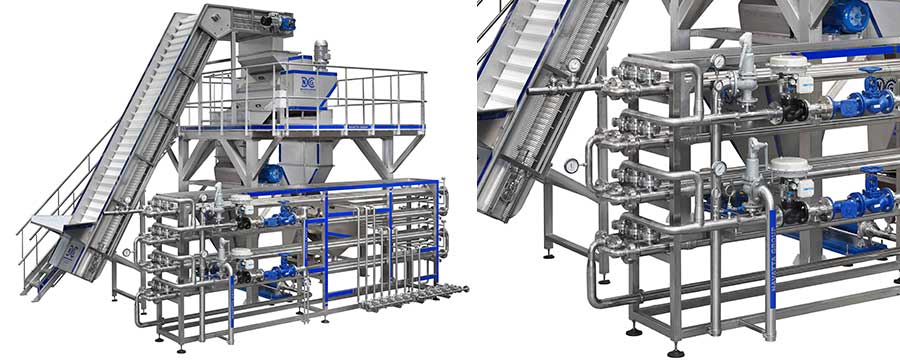

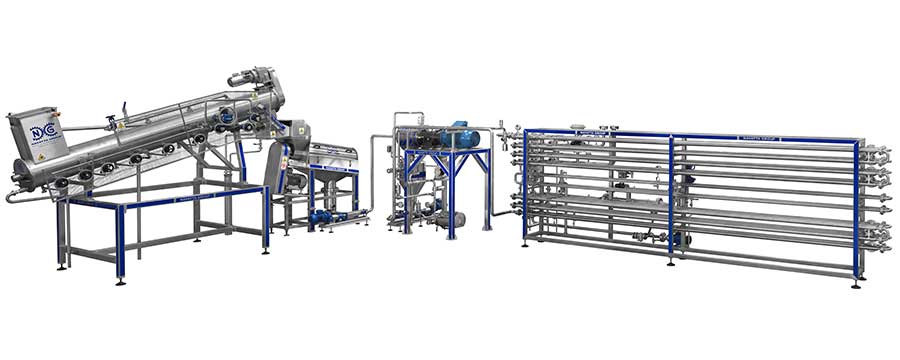

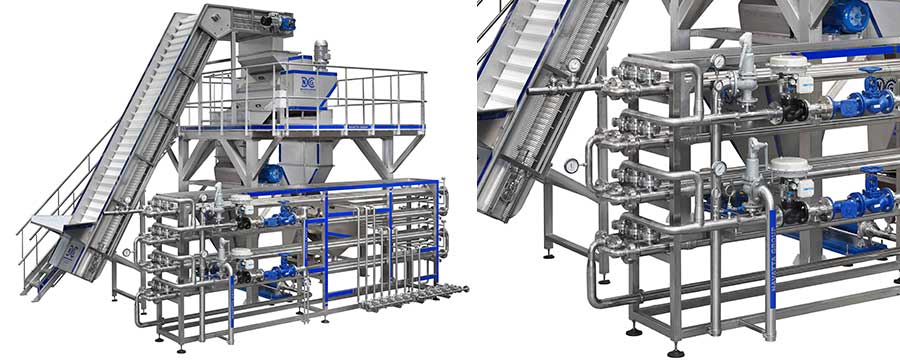

Mediterranean Fruit receiving, washing, de-stoning, de-pulping line with cold extraction and enzymatic inactivator

Mediterranean Fruit receiving, washing, de-stoning, de-pulping line with cold extraction and enzymatic inactivator

Pasteurizing Cooling-dryer tunnel for fruit puree, tomato paste and vegetable - 115 gr and 95 gr doypack

Falling film evaporator with aroma recovery

Turbulent thin film evaporator with aroma recovery

2 effect 2 stages + hot break forced circulation evaporator

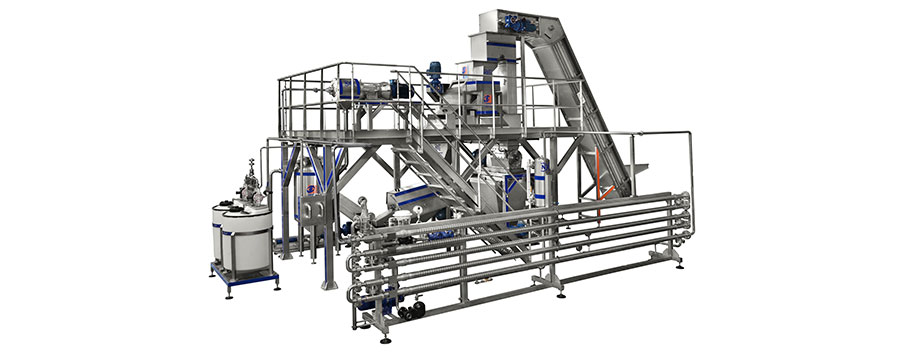

Complete washing and sorting system

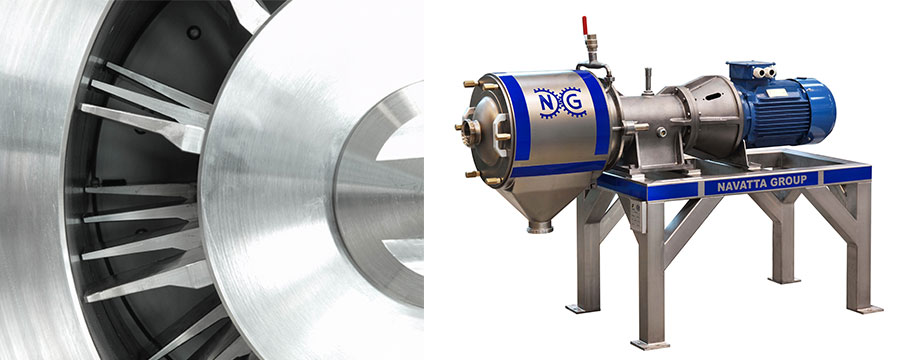

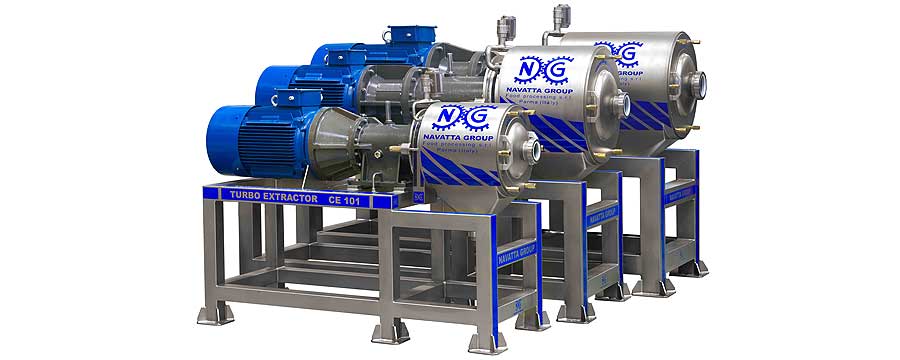

Fruit and tomato extraction system

Mediterranean fruit de-stoning extraction system

Crushing, pre-heating system for frozen blocks/drums

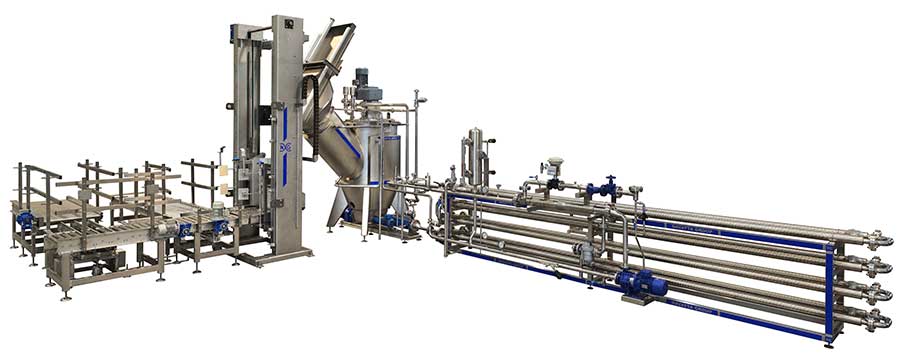

Juice aseptic sterilyzer + CIP system

Triple effect forced circulation evaporator + hot break

Mango destoner - stone cleaner

Double effect falling film evaporator for papaya, guava, mango, puree, pomegranate juice and grape juice.

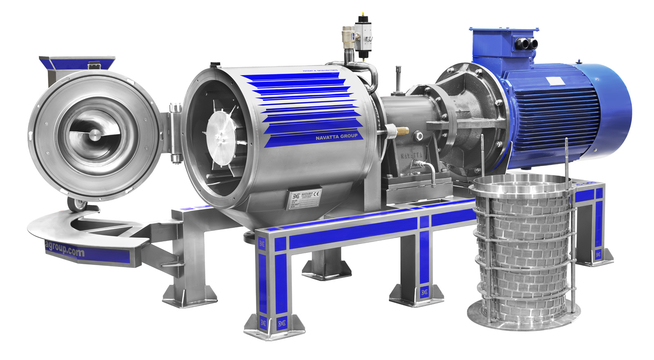

Turbulent thin film evaporator mod. VJ 57 for very high viscosity product

Italiano

Italiano Français

Français Español

Español Русский

Русский Português

Português