JAM LINES

The basic ingredients for jam are fruit, sugar and pectin.

The fruit can be fresh, IQF (Individual Quick Frozen) or frozen in blocks.

Fresh and IQF fruit are loaded directly with feed screw conveyors while the frozen blocks of fruit have to be chopped up before loading.

All the products are dosed in a pre-heating tank to bring them up to the concentration temperature.

Pectin and citric acid are dissolved in a water solution.

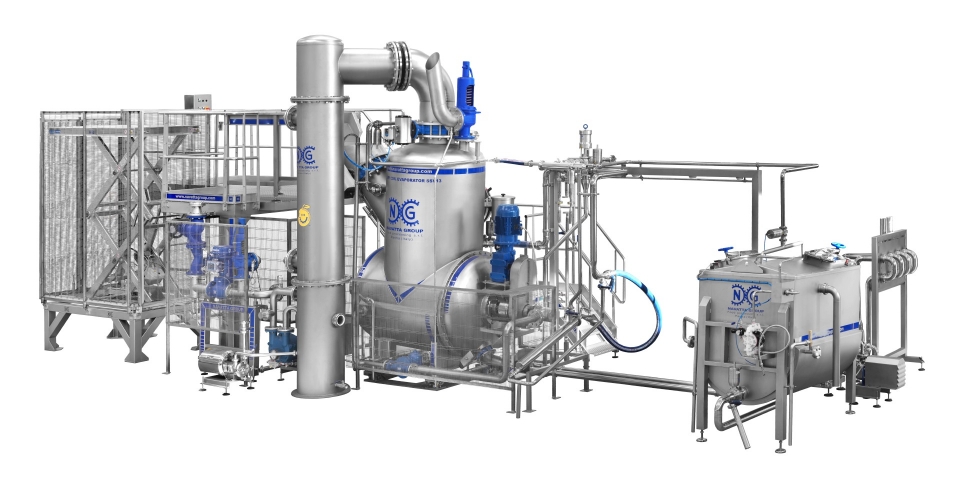

The mixture of fruit and sugar then goes into the concentrator where it is concentrated with the addition of pectin and citric acid.

In the case of products that are not very heat sensitive, they can also be pasteurized in the same concentrator.

Italiano

Italiano Français

Français Español

Español Русский

Русский Português

Português