FORMULATES

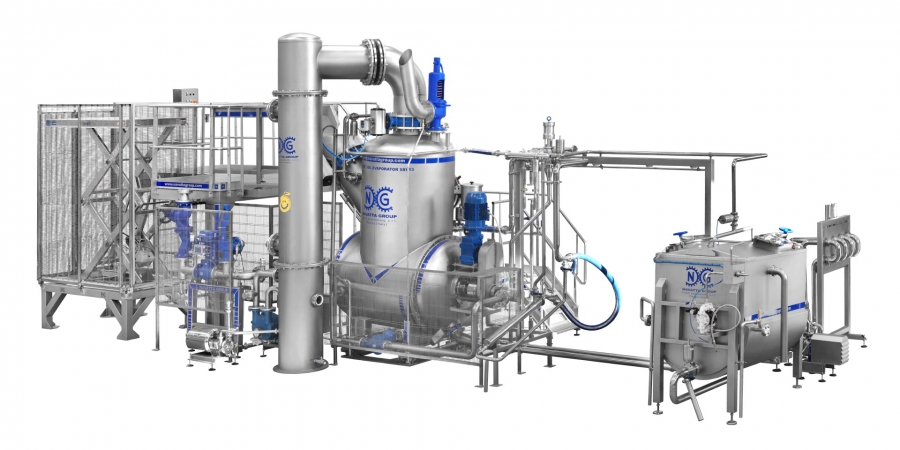

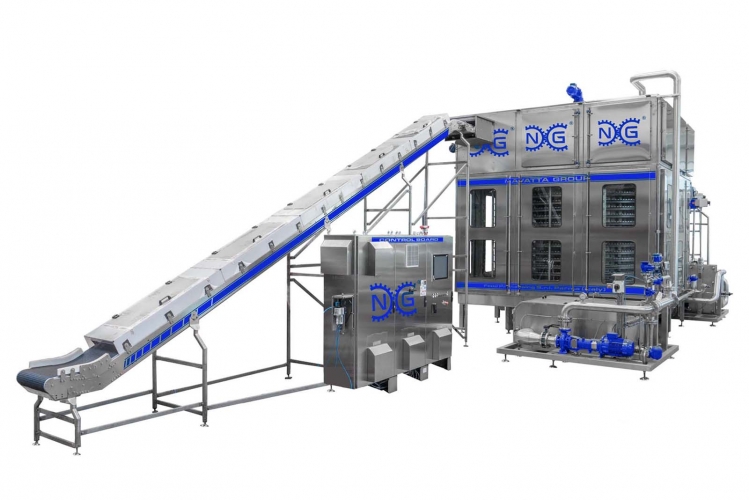

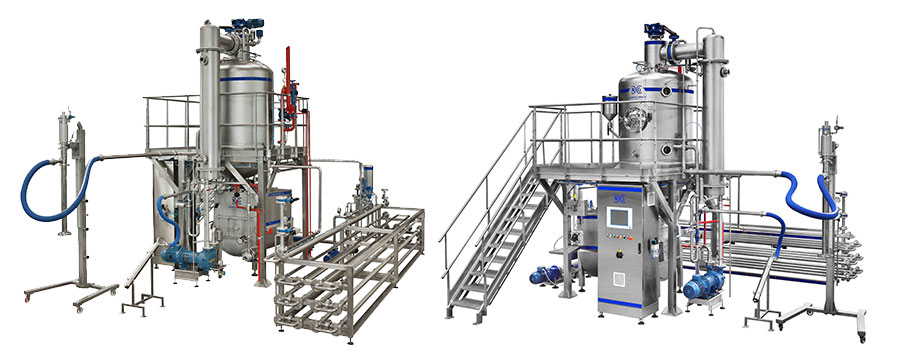

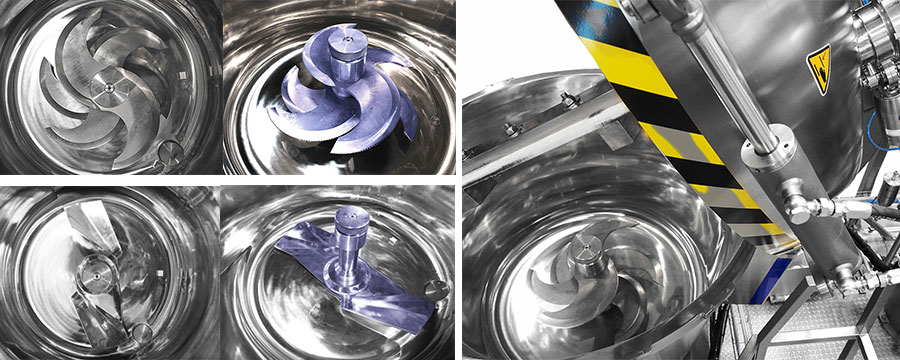

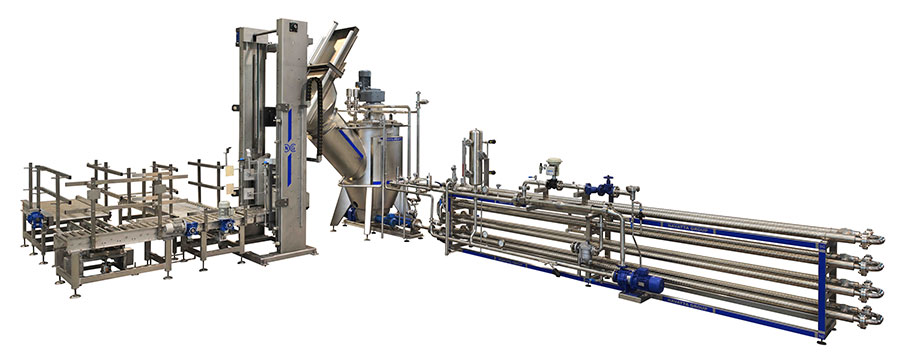

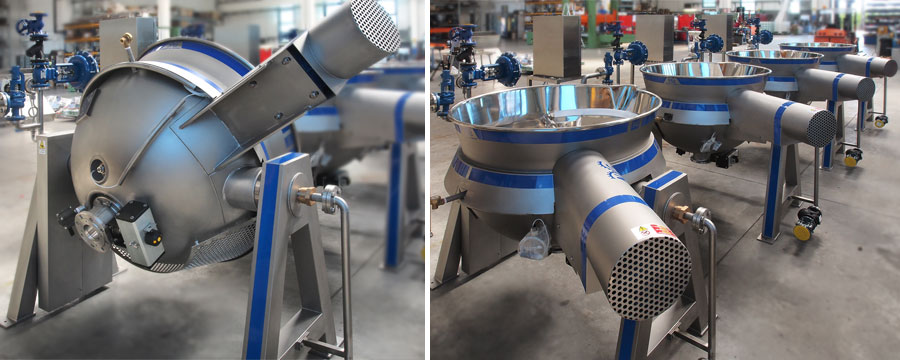

Industrial plants for products productions as premium nectars, smoothies, particulated jams, products for yoghurt or bakery or ice cream with high percentage of particulates and of high viscosity, sauces with or without particulates, marmalades, candy, ketchup, sauces, baby food, etc. etc. starting from components unloading to recipe dosing, mixing, mechanical / thermal stabilizing, to filling into any kind of package or in aseptic

Italiano

Italiano Français

Français Español

Español Русский

Русский Português

Português