[:it _i=”0″ _address=”0″ /]

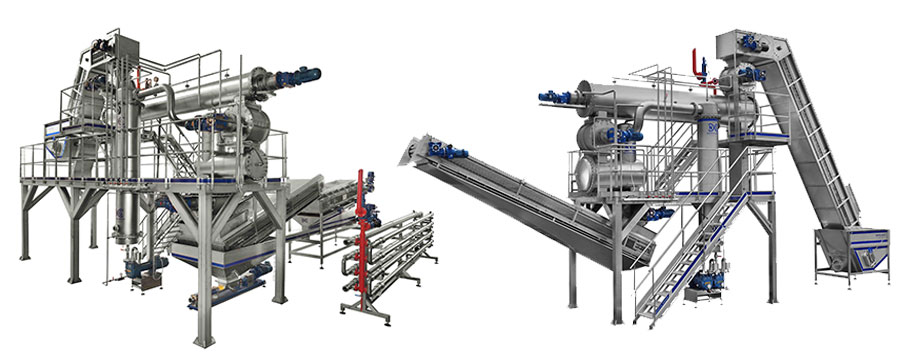

LINEE POMODORO

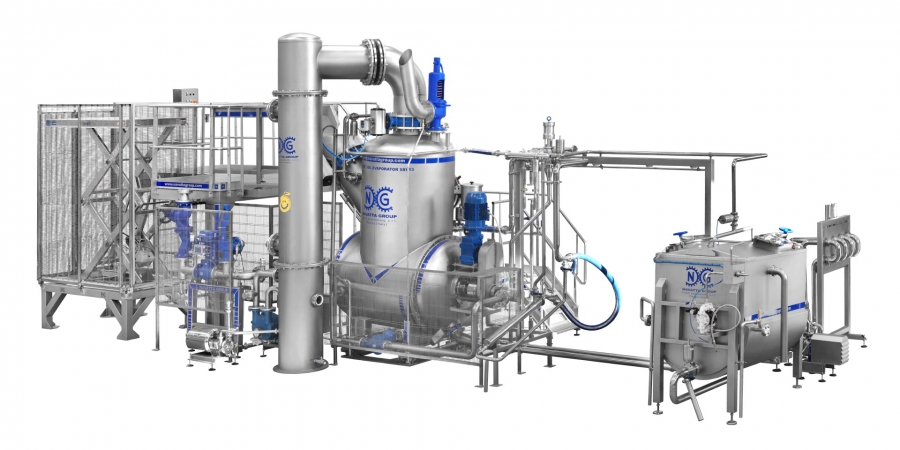

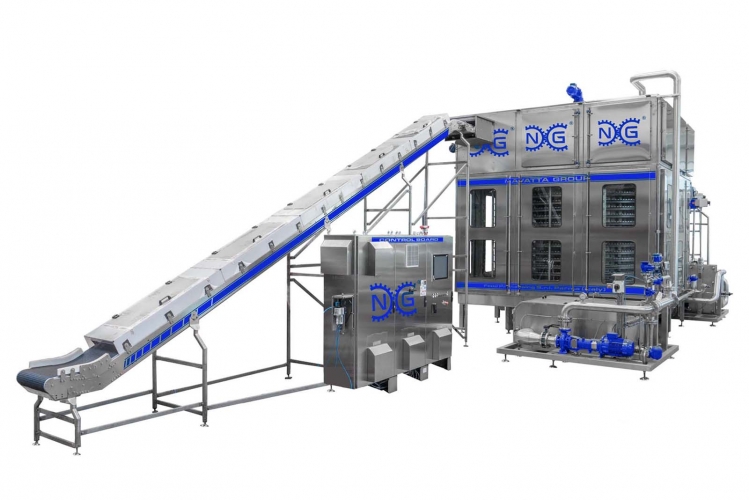

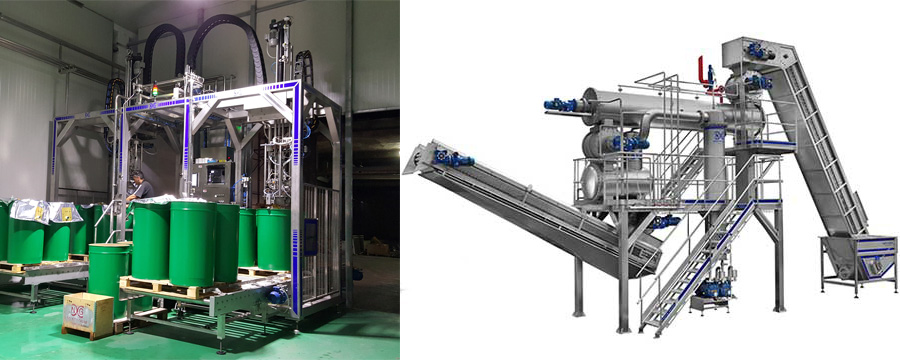

Le nostre linee permettono la produzione dei seguenti prodotti sia pastorizzati che sterilizzati, riempiti in asettico od in qualsiasi altro tipo di contenitori rigidi o flessibili:

- Doppio concentrato cold-break o hot-break

- Triplo concentrato cold-break

- Succo

- Passata

- Concentrato a 48-50 °Brix per la produzione di polveri

- Pomodori interi pelati in salsa di pomodoro

- Cubettati di pomodoro da pomodori pelati o non pelati, in salsa di pomodoro

- Polpa di pomodoro da pomodori pelati o non pelati in salsa di pomodoro

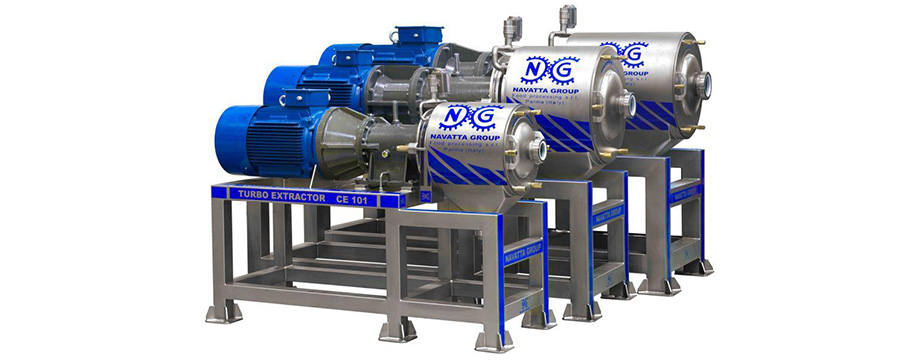

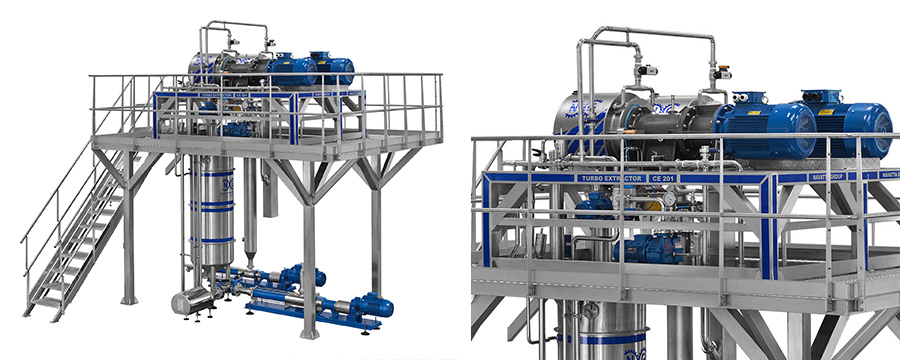

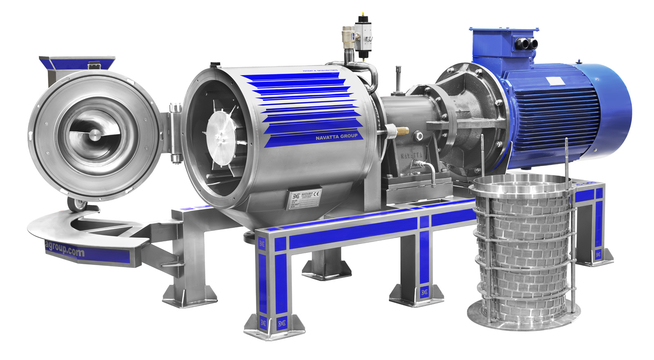

IMPIANTI POMODORO

TOMATO LINES

With our lines the following products can be made, both pasteurised and sterilised, filled in aseptic or in any other rigid or flexible containers:

- Double cold-break or hot-break concentrate

- Triple cold-break concentrate

- Juice

- Purée / Passata

- Concentrated at 48-50 degrees Brix for the production of powders

- Whole peeled tomatoes, in tomato sauce

- Diced tomatoes from peeled tomatoes or not peeled, in tomato sauce

- Crushed / tomato pulps from peeled tomatoes or not peeled tomatoes, in tomato sauce

TOMATO MACHINERIES

LIGNES DE TRANSFORMATION TOMATE

Nos lignes permettent la production des produits suivants, soit pasteurisés que stérilisés, remplis en manière aseptique ou dans autre types de récipients rigides ou flexibles :

- double concentré cold-break ou hot-break

- triple concentré cold-break

- jus de tomate

- purée de tomate

- concentré de tomate à 48-50 °Brix pour la fabrication de poudres

- Tomates pelées entières dans sauce tomate

- Tomates coupées en dés provenant de tomates pelées ou non pelées, dans sauce de tomate

- Pulpe de tomate provenant de tomates pelées et non pelées, dans sauce tomate

LÍNEAS DE TOMATE

Nuestras líneas permiten la producción de los siguientes productos sea pasteurizados qué esterilizados, llenados en aséptico o en cualquier otro tipo de contenedores rígidos o flexibles:

- Doble concentrado cold-break o hot-break

- Triple concentrado cold-break

- Jugo

- Puré

- Concentrado a 48-50 °Brix por la producción de polvos

- Tomatos enteros pelados en salsa de tomate

- Cubitos de tomate a partir de tomate pelados o no pelados, en salsa de tomate

- Polpa de tomate a partir de tomates pelados o non pelados en salsa de tomate

ЛИНИИ ПЕРЕРАБОТКИ ТОМАТОВ

Наши линию позволяют производить следующую продукцию как пастеризованную, так и стерилизованную, заполненную в асептические или другие жесткие или другие контейнеры:

- двойной концентрации cold-break или hot-break

- тройной концентрации cold-break

- пюре/пассата

- концентрат 48-50 Брикс для производства порошка

- очищенные целиковые помидоры в собственном соку

- томатные кубики из очищенных и неочищенных томатов в собственном соку

- томатная пульпа из очищенных и неочищенных томатов в собственном соку

LINHAS DE TOMATE

Nossas linhas de produção permitem que este produto seja esterilizado, pasteurizado, com enchimento asséptico ou em quaisquer outros recipientes rígidos ou flexíveis:

- Concentração dupla hot ou cold-break

- Concentração tripla cold-break

- Suco

- Purê

- Concentração a 48-50 ° Brix para a produção de produtos em pó

- Tomate pelado inteiro em molho de tomate

- Cubos de tomate pelado e não pelado, em molho de tomate

- Polpa de tomate a partir de tomates não pelados ou pelados em molho de tomate.

Italiano

Italiano English

English Français

Français Español

Español Português

Português